Welcome to our official website!

NEWS

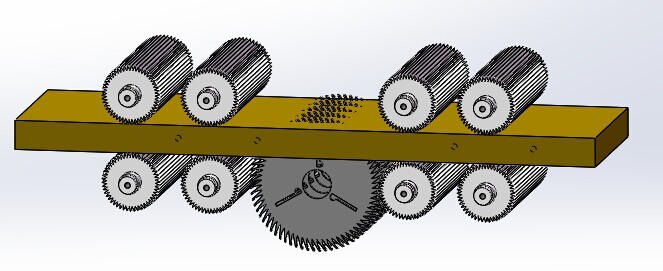

Key points for use of square wood multi-saw

Release time:

2022-01-05 15:21

Source:

When using sawn timber, it is generally necessary to increase the planing allowance, and the thickness of the saw blade plays a particularly important role in production and processing. Multi-blade saw adopts alloy steel saw blade, which is thicker than ordinary saw blade. The alloy blade on the saw blade rotates at high speed to cut wood. The surface of the board sawed by the square wood multi-slice saw is smooth and the size is accurate, which provides a reliable guarantee for the surface quality and thickness of the board. The ordinary saw blade can be directly used in some occasions where the requirements for the surface of the plate are not high. In theory, we hope that the thinner the saw blade is, the better. The material of the alloy saw blade base and the manufacturing process of the saw blade determine the thickness of the saw blade. If the thickness is too thin, many saw blades are easy to shake when working, affecting the cutting effect.

In the operation and use of the square wood multi-piece saw, there are many problems that need to be paid attention to in order to ensure a good cutting effect. When working, the workpiece should be fixed, and the wood feed should be consistent with the feed direction. Do not apply lateral pressure or curve cutting. The feed should be stable to avoid the saw blade hitting the workpiece, causing damage to the saw blade or flying out of the workpiece causing accidents. Once abnormal sound and vibration, rough cutting surface or peculiar smell are found, the operation shall be stopped immediately, and the fault shall be checked and eliminated in time to avoid accidents.

In addition, do not feed too fast when the square wood saw starts and stops cutting to avoid tooth breakage and damage. At the same time, the chip removal tank and slag suction device of the equipment should be unblocked to prevent slag from blocking and affecting production and health.

1. The equipment shall be intact, and the main shaft shall be free of deformation, diameter runout, firm installation and fixation, vibration and other phenomena.

2. Check whether the saw blade is damaged, whether the tooth shape is complete, whether the saw blade is smooth and flat, and whether there are other abnormalities to ensure the use of health.

3. When assembling the square wood multi-saw, ensure that the arrow direction of the saw blade is consistent with the rotation direction of the equipment spindle.

4. When installing the saw blade, keep the axis, chuck and flange clean, the inner diameter of the flange is consistent with the inner diameter of the saw blade, ensure that the flange is tightly combined with the saw blade, install the locating pin and tighten the nut. The size of the flange shall be appropriate, and the outer diameter shall not be less than 1/3 of the diameter of the saw blade.

5. Before the start of the square wood multi-blade saw equipment, under the condition of ensuring health, special personnel should be arranged to operate the equipment, gently push and idle, check whether the equipment rotates correctly, check whether there is vibration, and idle for a few minutes after the saw blade is installed, and work normally without slipping, swinging and jumping.

When selecting the thickness of the saw blade of the square wood multi-blade saw, the stability of the saw blade and the sawing material should be considered. It is well known that the multi-blade adjustment of woodworking machinery can not only transfer cutting force but also maintain its working stability. Good multi-blade not only has static geometric size and degree, but also has excellent dynamic characteristics. After repeated grinding, its service life is long, and the welding quality of cemented carbide is also very important. When cutting continuously with multiple blades, the temperature of the saw plate rises rapidly. In this case, high-quality saw blades can still maintain high standard accuracy, while low-quality saw blades will.

Square wood multi-saw

Related News

What are the differences and advantages between domestic saw and foreign saw

The quality of the multi-blade saw blade in the passage plays a vital role, because we all know that the adjustment and rotation of the multi-blade saw blade of woodworking machinery not only transfers the cutting force, but also maintains the stability of the work.

The quality and thickness of the multi-blade saw blade play an important role in the plate

In theory, we hope that the thinner the saw blade is, the better the thickness of the saw blade. The saw gap is actually a kind of consumption. The material of the alloy saw blade base and the process of manufacturing the saw blade determine the thickness of the saw blade. The thickness is too thin.